What surprising "secret passages" are there behind the belt conveyor?

Release Time : 2025-05-06

In the process of industrial modernization, belt conveyors, as an efficient material handling equipment, are widely used in many fields such as mines, ports, electricity, and metallurgy. It seems to have a simple structure and a single function, but behind it are many little-known technical details and innovative designs. These "secret passages" not only reflect engineering wisdom, but also promote the sustainable development of the industry. This article will start from the basic principles of belt conveyors and deeply explore the amazing design concepts, technological innovations and safety mechanisms behind them.

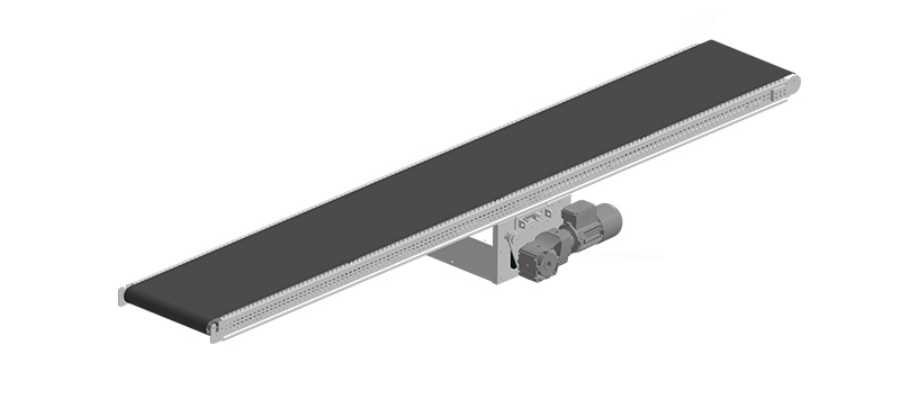

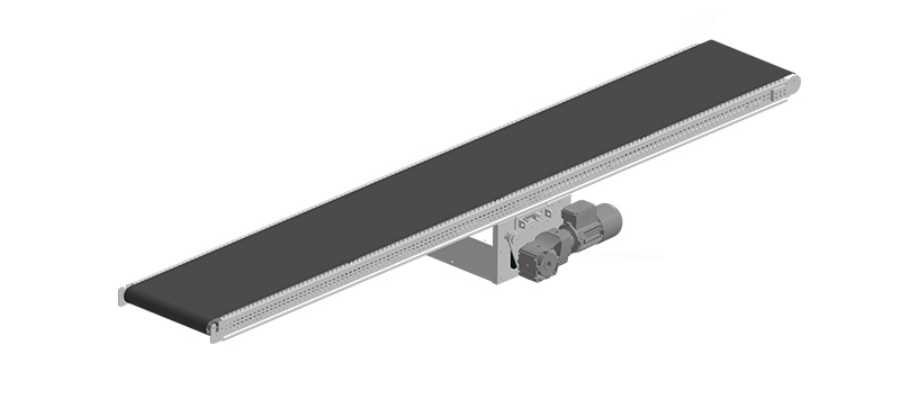

1. Basic structure and working principle of belt conveyors

The belt conveyor consists of a drive device, a transmission roller, a redirecting roller, a bearing roller, a return roller, a tensioning device, a conveyor belt, and a support structure. Its basic working principle is to drive the reducer through the motor to drive the roller to rotate, thereby driving the conveyor belt to operate continuously and realize the continuous transportation of materials.

Although the structure seems simple, in actual applications, in order to adapt to different working conditions (such as long-distance transportation, large-angle transportation, high temperature or corrosive environment), the design of the belt conveyor needs to consider multiple complex factors. For example:

- Conveyor belt material selection: choose different materials such as rubber, PVC, metal mesh belt, etc. according to the properties of the conveyed material (such as temperature, hardness, and corrosiveness).

- Optimization of the tensioning system: ensure that the conveyor belt maintains appropriate tension during operation to prevent slipping or deviation.

- Multi-point drive technology: when used for long-distance transportation, multiple drive points are set on the conveying line to reduce the power demand of a single motor and improve stability.

These design "details" constitute the "secret channel" for the efficient operation of the belt conveyor.

2.Secret Channel 1: Revolutionary breakthrough of permanent magnet direct drive technology

Traditional belt conveyors usually use asynchronous motor + reducer drive mode. Although this solution is mature, it has problems such as low efficiency, high noise, and frequent maintenance. In recent years, with the development of permanent magnet synchronous motor technology, permanent magnet direct drive system has gradually become the new favorite of the industry.

Permanent magnet direct drive technology eliminates the traditional reduction box, and the permanent magnet motor directly drives the roller, which has the following advantages:

1. High efficiency and energy saving: The efficiency of the permanent magnet motor can reach more than 95%, which saves more than 30% energy compared with the traditional system.

2. Low noise and environmental protection: The gearless transmission structure significantly reduces the operating noise and improves the working environment.

3. Maintenance-free design: After the reduction box is cancelled, the maintenance costs such as lubricating oil replacement and gear wear are reduced.

4. Intelligent control: It can integrate functions such as variable frequency speed regulation and intelligent monitoring to improve the automation level of the system.

This technological innovation is like a "secret passage" leading to green manufacturing and intelligent manufacturing, which is quietly changing the face of the entire conveying industry.

3. "Secret Passage" 2: Intelligent Monitoring and Predictive Maintenance System

Modern industry has higher and higher requirements for the reliability of equipment, and the traditional regular maintenance method can no longer meet the needs of high-efficiency production. Therefore, more and more belt conveyors are equipped with intelligent monitoring systems to realize real-time perception of equipment status and fault warning.

Such systems usually include the following key technical modules:

- Vibration sensors and temperature monitoring: used to detect the status of key components such as bearings and rollers.

- Image recognition and AI algorithms: through cameras and AI analysis, identify belt deviation, tearing, foreign body jamming and other problems.

- Wireless communication and edge computing: upload the collected data to the cloud platform for big data analysis and trend prediction.

- Remote diagnosis and automatic alarm: once an abnormality is found, the system can automatically notify the operation and maintenance personnel and provide maintenance suggestions.

The application of these technologies enables the belt conveyor to have the ability of "self-perception", forming an invisible "digital channel", which greatly improves the safety and intelligence level of the system.

4. "Secret Channel" Three: Innovative Solutions for Special Working Conditions

In some extreme environments, such as underground mines, open-pit mines, offshore platforms, etc., ordinary belt conveyors are difficult to perform tasks. To this end, engineers have developed a series of innovative solutions for special scenarios:

1. High-angle belt conveyor

In mountainous mining areas or shafts, materials need to be transported vertically or nearly vertically. Traditional bucket elevators are less efficient, while high-angle belt conveyors can achieve a maximum conveying angle of 90°. Its core technologies are:

- Conveyor belts with special patterns or baffle designs;

- Multi-stage tensioning mechanisms;

- Intelligent anti-skid control systems.

2. Tubular belt conveyors

In order to solve the problems of dust pollution and space limitations, tubular belt conveyors came into being. Its conveyor belt forms a closed circular tube shape during operation, which can prevent material leakage and achieve curved turns. It is suitable for places with high environmental protection requirements such as urban garbage disposal and chemical plants.

3. Underwater belt conveyors

In marine mining and dredging projects, underwater belt conveyors can operate stably at depths of tens or even hundreds of meters underwater. Its sealing structure, anti-corrosion coating and pressure-resistant design enable it to work for a long time in high-pressure and high-salinity environments.

These special conveying technologies constitute a "secret passage" to extreme environmental applications, demonstrating the strong adaptability of human engineering technology.

5. "Secret Passage" 4: Safety Protection and Human-Machine Collaborative Design

Although belt conveyors are highly efficient and highly automated, there are still certain safety hazards during their operation, such as mechanical pinching, belt breakage, and fire risks. Therefore, safety design has also become a focus of engineers.

1. Multiple protection mechanisms

Modern belt conveyors are generally equipped with the following safety devices:

- Emergency pull rope switch: arranged along the conveyor line, which can quickly stop the machine in an emergency;

- Deviation switch and automatic deviation correction device: prevent the belt from deviating from the track;

- Smoke and temperature sensors: prevent fire accidents;

- Broken belt catcher: prevent secondary damage after the belt breaks.

2. Human-machine interface (HMI)

Operators can view the equipment status, adjust parameters, and receive alarm information through the touch screen or remote terminal, which greatly improves the convenience and safety of operation.

3. Modular and quick disassembly and assembly design

It is convenient for daily maintenance and replacement of parts, shortens downtime, and improves equipment availability.

These safety measures and humanized design have built a "life channel" to ensure the safety of personnel and equipment.

6. Green and intelligent integrated development

With the increasing global attention to carbon emissions and resource recycling, the belt conveyor industry is also evolving towards green, low-carbon and intelligent.

- Green energy drive: Renewable energy power supply systems such as solar energy and wind energy are being explored for belt conveyor systems in remote areas.

- Artificial intelligence assisted decision-making: The AI-based scheduling optimization system can dynamically adjust the operation strategy according to material flow and energy consumption data.

- Digital twins and virtual simulation: By building a digital mirror of the equipment, various operating conditions are simulated in advance, and the design and operation and maintenance solutions are optimized.

The future belt conveyor will no longer be just a cold steel machine, but an intelligent body that integrates energy management, data analysis, and autonomous learning capabilities, and will truly become the "smart logistics core" in the era of Industry 4.0.

The belt conveyor, a seemingly ordinary industrial equipment, actually contains countless engineering wisdom and technological innovations. From permanent magnet direct drive to intelligent monitoring, from special transportation to safety assurance, each "secret passage" represents the unremitting pursuit of mankind on the road of industrial progress. They may not be seen by people, but they really affect every aspect of our lives.

As the old saying goes: "True greatness is often hidden in the most ordinary places." The "secret passage" behind the belt conveyor is one of the most moving landscapes in modern industrial civilization.

1. Basic structure and working principle of belt conveyors

The belt conveyor consists of a drive device, a transmission roller, a redirecting roller, a bearing roller, a return roller, a tensioning device, a conveyor belt, and a support structure. Its basic working principle is to drive the reducer through the motor to drive the roller to rotate, thereby driving the conveyor belt to operate continuously and realize the continuous transportation of materials.

Although the structure seems simple, in actual applications, in order to adapt to different working conditions (such as long-distance transportation, large-angle transportation, high temperature or corrosive environment), the design of the belt conveyor needs to consider multiple complex factors. For example:

- Conveyor belt material selection: choose different materials such as rubber, PVC, metal mesh belt, etc. according to the properties of the conveyed material (such as temperature, hardness, and corrosiveness).

- Optimization of the tensioning system: ensure that the conveyor belt maintains appropriate tension during operation to prevent slipping or deviation.

- Multi-point drive technology: when used for long-distance transportation, multiple drive points are set on the conveying line to reduce the power demand of a single motor and improve stability.

These design "details" constitute the "secret channel" for the efficient operation of the belt conveyor.

2.Secret Channel 1: Revolutionary breakthrough of permanent magnet direct drive technology

Traditional belt conveyors usually use asynchronous motor + reducer drive mode. Although this solution is mature, it has problems such as low efficiency, high noise, and frequent maintenance. In recent years, with the development of permanent magnet synchronous motor technology, permanent magnet direct drive system has gradually become the new favorite of the industry.

Permanent magnet direct drive technology eliminates the traditional reduction box, and the permanent magnet motor directly drives the roller, which has the following advantages:

1. High efficiency and energy saving: The efficiency of the permanent magnet motor can reach more than 95%, which saves more than 30% energy compared with the traditional system.

2. Low noise and environmental protection: The gearless transmission structure significantly reduces the operating noise and improves the working environment.

3. Maintenance-free design: After the reduction box is cancelled, the maintenance costs such as lubricating oil replacement and gear wear are reduced.

4. Intelligent control: It can integrate functions such as variable frequency speed regulation and intelligent monitoring to improve the automation level of the system.

This technological innovation is like a "secret passage" leading to green manufacturing and intelligent manufacturing, which is quietly changing the face of the entire conveying industry.

3. "Secret Passage" 2: Intelligent Monitoring and Predictive Maintenance System

Modern industry has higher and higher requirements for the reliability of equipment, and the traditional regular maintenance method can no longer meet the needs of high-efficiency production. Therefore, more and more belt conveyors are equipped with intelligent monitoring systems to realize real-time perception of equipment status and fault warning.

Such systems usually include the following key technical modules:

- Vibration sensors and temperature monitoring: used to detect the status of key components such as bearings and rollers.

- Image recognition and AI algorithms: through cameras and AI analysis, identify belt deviation, tearing, foreign body jamming and other problems.

- Wireless communication and edge computing: upload the collected data to the cloud platform for big data analysis and trend prediction.

- Remote diagnosis and automatic alarm: once an abnormality is found, the system can automatically notify the operation and maintenance personnel and provide maintenance suggestions.

The application of these technologies enables the belt conveyor to have the ability of "self-perception", forming an invisible "digital channel", which greatly improves the safety and intelligence level of the system.

4. "Secret Channel" Three: Innovative Solutions for Special Working Conditions

In some extreme environments, such as underground mines, open-pit mines, offshore platforms, etc., ordinary belt conveyors are difficult to perform tasks. To this end, engineers have developed a series of innovative solutions for special scenarios:

1. High-angle belt conveyor

In mountainous mining areas or shafts, materials need to be transported vertically or nearly vertically. Traditional bucket elevators are less efficient, while high-angle belt conveyors can achieve a maximum conveying angle of 90°. Its core technologies are:

- Conveyor belts with special patterns or baffle designs;

- Multi-stage tensioning mechanisms;

- Intelligent anti-skid control systems.

2. Tubular belt conveyors

In order to solve the problems of dust pollution and space limitations, tubular belt conveyors came into being. Its conveyor belt forms a closed circular tube shape during operation, which can prevent material leakage and achieve curved turns. It is suitable for places with high environmental protection requirements such as urban garbage disposal and chemical plants.

3. Underwater belt conveyors

In marine mining and dredging projects, underwater belt conveyors can operate stably at depths of tens or even hundreds of meters underwater. Its sealing structure, anti-corrosion coating and pressure-resistant design enable it to work for a long time in high-pressure and high-salinity environments.

These special conveying technologies constitute a "secret passage" to extreme environmental applications, demonstrating the strong adaptability of human engineering technology.

5. "Secret Passage" 4: Safety Protection and Human-Machine Collaborative Design

Although belt conveyors are highly efficient and highly automated, there are still certain safety hazards during their operation, such as mechanical pinching, belt breakage, and fire risks. Therefore, safety design has also become a focus of engineers.

1. Multiple protection mechanisms

Modern belt conveyors are generally equipped with the following safety devices:

- Emergency pull rope switch: arranged along the conveyor line, which can quickly stop the machine in an emergency;

- Deviation switch and automatic deviation correction device: prevent the belt from deviating from the track;

- Smoke and temperature sensors: prevent fire accidents;

- Broken belt catcher: prevent secondary damage after the belt breaks.

2. Human-machine interface (HMI)

Operators can view the equipment status, adjust parameters, and receive alarm information through the touch screen or remote terminal, which greatly improves the convenience and safety of operation.

3. Modular and quick disassembly and assembly design

It is convenient for daily maintenance and replacement of parts, shortens downtime, and improves equipment availability.

These safety measures and humanized design have built a "life channel" to ensure the safety of personnel and equipment.

6. Green and intelligent integrated development

With the increasing global attention to carbon emissions and resource recycling, the belt conveyor industry is also evolving towards green, low-carbon and intelligent.

- Green energy drive: Renewable energy power supply systems such as solar energy and wind energy are being explored for belt conveyor systems in remote areas.

- Artificial intelligence assisted decision-making: The AI-based scheduling optimization system can dynamically adjust the operation strategy according to material flow and energy consumption data.

- Digital twins and virtual simulation: By building a digital mirror of the equipment, various operating conditions are simulated in advance, and the design and operation and maintenance solutions are optimized.

The future belt conveyor will no longer be just a cold steel machine, but an intelligent body that integrates energy management, data analysis, and autonomous learning capabilities, and will truly become the "smart logistics core" in the era of Industry 4.0.

The belt conveyor, a seemingly ordinary industrial equipment, actually contains countless engineering wisdom and technological innovations. From permanent magnet direct drive to intelligent monitoring, from special transportation to safety assurance, each "secret passage" represents the unremitting pursuit of mankind on the road of industrial progress. They may not be seen by people, but they really affect every aspect of our lives.

As the old saying goes: "True greatness is often hidden in the most ordinary places." The "secret passage" behind the belt conveyor is one of the most moving landscapes in modern industrial civilization.