Say goodbye to manual sorting, how does the direct-drive roller sorter reshape logistics efficiency?

Release Time : 2025-04-25

In today's booming logistics industry, efficiency and accuracy have become key indicators for measuring the level of logistics operations. The traditional manual sorting method is not only inefficient, but also prone to errors, and it is difficult to meet the needs of modern logistics. The emergence of direct-drive roller sorters has brought a new solution to logistics sorting and is reshaping logistics efficiency.

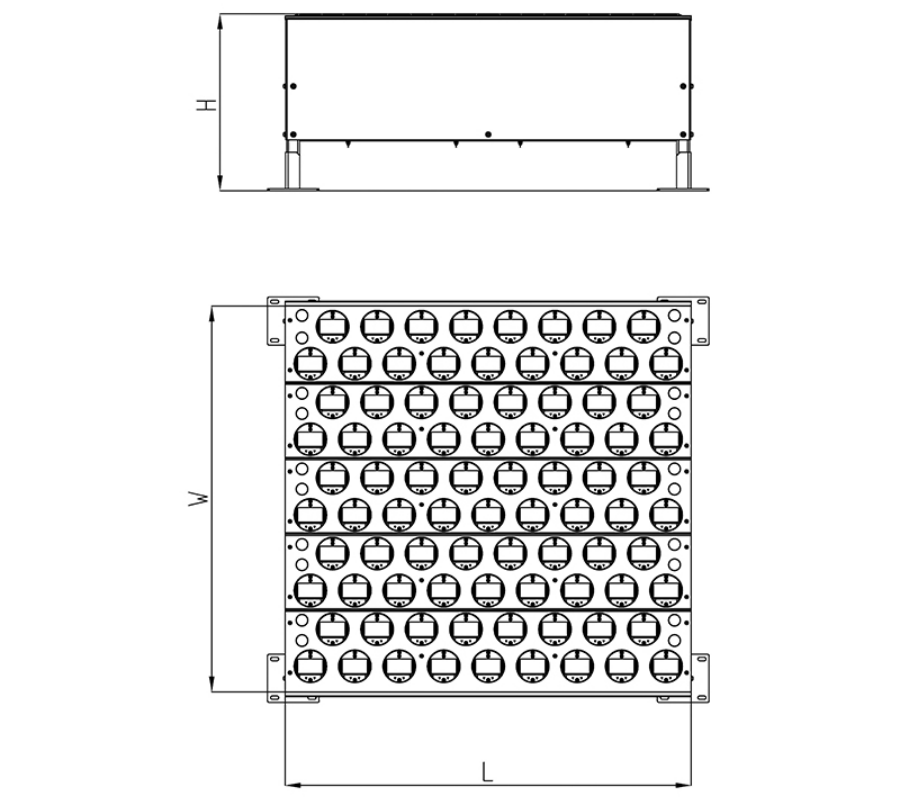

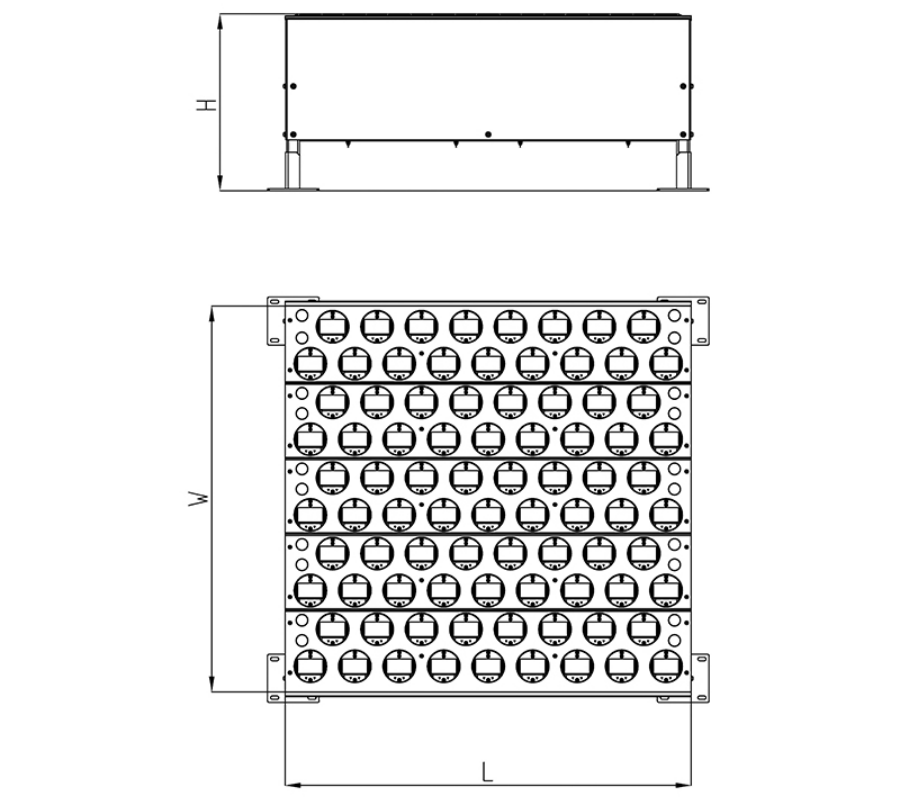

Direct-drive roller sorters, also known as electric roller swing sorters or electric roller swing sorting systems, are an efficient automated sorting equipment. It is widely used in logistics centers, warehouses, postal services, e-commerce, retail, manufacturing and other industries, and can quickly and accurately sort items to different destinations. The core component of the sorter is the swing roller (or swing arm), which swings left and right under power drive to guide items to the preset sorting outlet.

1. Application scenarios of direct-drive roller sorters

Warehouse conveyor sorting machine operation

In the daily operation of the warehouse, the conveyor belt undertakes the important task of cargo transportation. Direct-drive roller sorters play a key role in warehouse conveyor belt sorting operations. They can efficiently transfer goods from one conveyor belt to another, or sort goods to designated storage locations. In the past, manual operations such as this not only took a lot of time and manpower, but were also prone to problems such as goods falling and sorting errors. The direct-drive roller sorter, with its efficient sorting capabilities and stable performance, makes warehouse operations more orderly and efficient. The goods move quickly on the conveyor belt, and when they pass through the direct-drive roller sorter, they can be quickly and accurately guided to the corresponding position, greatly improving the warehouse's goods turnover rate.

Warehouse sorting operations

There are many types of goods in the warehouse, and the order requirements are also different. The direct-drive roller sorter can sort the goods quickly and accurately according to information such as goods attributes and order requirements. For example, for goods of different sizes and weights, the direct-drive roller sorter can achieve accurate sorting by adjusting the angle and speed of the swinging roller. This sorting method not only improves the storage efficiency of the warehouse, enabling goods to find a suitable storage location more quickly, but also reduces the error rate of manual sorting. During manual sorting, sorting errors are prone to occur due to fatigue, negligence, etc., while direct-drive drum sorters can operate strictly according to preset procedures to ensure the accuracy of sorting, making warehouse management more intelligent and automated.

Logistics sorting center

The logistics sorting center is an important place for the distribution of goods, and usually needs to handle a large number of goods from different channels and regions. With its efficient sorting ability and flexibility, the direct-drive drum sorter has become one of the indispensable equipment for logistics sorting centers. It can quickly and accurately sort goods to different logistics routes or storage areas. During the peak period of logistics, the direct-drive drum sorter can operate continuously and stably, greatly improving the overall operational efficiency of the logistics sorting center. Compared with traditional manual sorting, the direct-drive drum sorter can handle more goods in a shorter time, reduce the backlog of goods, and improve the timeliness of logistics.

2. Advantages and characteristics of direct-drive drum sorters

Efficient sorting

The direct-drive drum sorter adopts direct drive technology, which is the key to its efficient sorting. Direct drive technology eliminates many intermediate links in the traditional transmission system, such as belts and chains, so that power can be directly transmitted to the roller. In this way, the roller responds faster and can quickly swing according to the control signal to achieve fast and accurate sorting. In practical applications, direct drive roller sorters can process a large amount of goods in a short time, greatly improving the sorting efficiency and meeting the needs of modern logistics for rapid processing of goods.

Good stability

Direct drive technology reduces the loss and interference in the energy transfer process, making the roller rotation more stable and reliable. Due to the presence of multiple transmission components, the traditional transmission system is prone to wear and looseness, resulting in unstable roller rotation and affecting the accuracy of sorting. The direct drive roller sorter avoids these problems, and its stable performance ensures the smooth progress of the sorting process. Even in the case of long-term continuous operation, the direct drive roller sorter can maintain a stable sorting state, reducing the probability of failure and improving the reliability of the equipment.

Low maintenance cost

The structure of the direct drive roller sorter is relatively simple, without complex transmission components, which makes its maintenance cost low. Traditional transmission systems require regular replacement of wearing parts such as belts and chains, which requires a large amount of maintenance work and high costs. However, direct-drive roller sorters only need to regularly inspect and maintain the motor and roller, which greatly reduces operating costs. In addition, the failure rate of direct-drive roller sorters is low, which reduces downtime caused by equipment maintenance and improves equipment utilization.

Energy saving and environmental protection

Direct drive technology improves the overall efficiency of the system, reduces energy waste, and conforms to today's energy-saving and environmental protection concepts. Because direct drive technology reduces the loss in the energy transfer process, the motor can more efficiently convert electrical energy into mechanical energy, reducing energy consumption. In the logistics industry, a large number of equipment operations require a lot of energy. The use of direct-drive roller sorters can effectively reduce energy use, reduce the operating costs of enterprises, and also contribute to environmental protection.

3. The reshaping of logistics efficiency by direct-drive roller sorters

The emergence of direct-drive roller sorters has completely changed the mode of traditional logistics sorting. With its advantages of high efficiency, stability, low maintenance cost, energy saving and environmental protection, it has become the core equipment of modern logistics sorting. In warehouses and logistics sorting centers, the application of direct-drive roller sorting machines makes cargo sorting faster and more accurate, greatly improving the operational efficiency of logistics. At the same time, it also reduces the use of manpower, reduces labor costs, and improves the economic benefits of enterprises.

With the continuous development of the logistics industry, the requirements for logistics efficiency will become higher and higher. As an advanced automated sorting equipment, the direct-drive roller sorting machine will continue to develop and improve. In the future, it is expected to make greater breakthroughs in intelligence and automation, and combine with technologies such as the Internet of Things and big data to achieve more accurate and efficient sorting. For example, by combining with the Internet of Things technology, the direct-drive roller sorting machine can obtain the information of the goods in real time and perform personalized sorting according to the characteristics and needs of the goods; combined with big data technology, the sorting process can be optimized to improve sorting efficiency and quality.

In short, the direct-drive roller sorting machine, with its excellent performance and advantages, is reshaping logistics efficiency and bringing new opportunities and challenges to the development of the logistics industry. Logistics companies should actively adopt advanced equipment such as direct-drive roller sorting machines to enhance their competitiveness to adapt to market needs and development.

Direct-drive roller sorters, also known as electric roller swing sorters or electric roller swing sorting systems, are an efficient automated sorting equipment. It is widely used in logistics centers, warehouses, postal services, e-commerce, retail, manufacturing and other industries, and can quickly and accurately sort items to different destinations. The core component of the sorter is the swing roller (or swing arm), which swings left and right under power drive to guide items to the preset sorting outlet.

1. Application scenarios of direct-drive roller sorters

Warehouse conveyor sorting machine operation

In the daily operation of the warehouse, the conveyor belt undertakes the important task of cargo transportation. Direct-drive roller sorters play a key role in warehouse conveyor belt sorting operations. They can efficiently transfer goods from one conveyor belt to another, or sort goods to designated storage locations. In the past, manual operations such as this not only took a lot of time and manpower, but were also prone to problems such as goods falling and sorting errors. The direct-drive roller sorter, with its efficient sorting capabilities and stable performance, makes warehouse operations more orderly and efficient. The goods move quickly on the conveyor belt, and when they pass through the direct-drive roller sorter, they can be quickly and accurately guided to the corresponding position, greatly improving the warehouse's goods turnover rate.

Warehouse sorting operations

There are many types of goods in the warehouse, and the order requirements are also different. The direct-drive roller sorter can sort the goods quickly and accurately according to information such as goods attributes and order requirements. For example, for goods of different sizes and weights, the direct-drive roller sorter can achieve accurate sorting by adjusting the angle and speed of the swinging roller. This sorting method not only improves the storage efficiency of the warehouse, enabling goods to find a suitable storage location more quickly, but also reduces the error rate of manual sorting. During manual sorting, sorting errors are prone to occur due to fatigue, negligence, etc., while direct-drive drum sorters can operate strictly according to preset procedures to ensure the accuracy of sorting, making warehouse management more intelligent and automated.

Logistics sorting center

The logistics sorting center is an important place for the distribution of goods, and usually needs to handle a large number of goods from different channels and regions. With its efficient sorting ability and flexibility, the direct-drive drum sorter has become one of the indispensable equipment for logistics sorting centers. It can quickly and accurately sort goods to different logistics routes or storage areas. During the peak period of logistics, the direct-drive drum sorter can operate continuously and stably, greatly improving the overall operational efficiency of the logistics sorting center. Compared with traditional manual sorting, the direct-drive drum sorter can handle more goods in a shorter time, reduce the backlog of goods, and improve the timeliness of logistics.

2. Advantages and characteristics of direct-drive drum sorters

Efficient sorting

The direct-drive drum sorter adopts direct drive technology, which is the key to its efficient sorting. Direct drive technology eliminates many intermediate links in the traditional transmission system, such as belts and chains, so that power can be directly transmitted to the roller. In this way, the roller responds faster and can quickly swing according to the control signal to achieve fast and accurate sorting. In practical applications, direct drive roller sorters can process a large amount of goods in a short time, greatly improving the sorting efficiency and meeting the needs of modern logistics for rapid processing of goods.

Good stability

Direct drive technology reduces the loss and interference in the energy transfer process, making the roller rotation more stable and reliable. Due to the presence of multiple transmission components, the traditional transmission system is prone to wear and looseness, resulting in unstable roller rotation and affecting the accuracy of sorting. The direct drive roller sorter avoids these problems, and its stable performance ensures the smooth progress of the sorting process. Even in the case of long-term continuous operation, the direct drive roller sorter can maintain a stable sorting state, reducing the probability of failure and improving the reliability of the equipment.

Low maintenance cost

The structure of the direct drive roller sorter is relatively simple, without complex transmission components, which makes its maintenance cost low. Traditional transmission systems require regular replacement of wearing parts such as belts and chains, which requires a large amount of maintenance work and high costs. However, direct-drive roller sorters only need to regularly inspect and maintain the motor and roller, which greatly reduces operating costs. In addition, the failure rate of direct-drive roller sorters is low, which reduces downtime caused by equipment maintenance and improves equipment utilization.

Energy saving and environmental protection

Direct drive technology improves the overall efficiency of the system, reduces energy waste, and conforms to today's energy-saving and environmental protection concepts. Because direct drive technology reduces the loss in the energy transfer process, the motor can more efficiently convert electrical energy into mechanical energy, reducing energy consumption. In the logistics industry, a large number of equipment operations require a lot of energy. The use of direct-drive roller sorters can effectively reduce energy use, reduce the operating costs of enterprises, and also contribute to environmental protection.

3. The reshaping of logistics efficiency by direct-drive roller sorters

The emergence of direct-drive roller sorters has completely changed the mode of traditional logistics sorting. With its advantages of high efficiency, stability, low maintenance cost, energy saving and environmental protection, it has become the core equipment of modern logistics sorting. In warehouses and logistics sorting centers, the application of direct-drive roller sorting machines makes cargo sorting faster and more accurate, greatly improving the operational efficiency of logistics. At the same time, it also reduces the use of manpower, reduces labor costs, and improves the economic benefits of enterprises.

With the continuous development of the logistics industry, the requirements for logistics efficiency will become higher and higher. As an advanced automated sorting equipment, the direct-drive roller sorting machine will continue to develop and improve. In the future, it is expected to make greater breakthroughs in intelligence and automation, and combine with technologies such as the Internet of Things and big data to achieve more accurate and efficient sorting. For example, by combining with the Internet of Things technology, the direct-drive roller sorting machine can obtain the information of the goods in real time and perform personalized sorting according to the characteristics and needs of the goods; combined with big data technology, the sorting process can be optimized to improve sorting efficiency and quality.

In short, the direct-drive roller sorting machine, with its excellent performance and advantages, is reshaping logistics efficiency and bringing new opportunities and challenges to the development of the logistics industry. Logistics companies should actively adopt advanced equipment such as direct-drive roller sorting machines to enhance their competitiveness to adapt to market needs and development.