How does a 2D bulk flow singulator optimize parcel handling in e-commerce warehousing?

Release Time : 2025-11-11

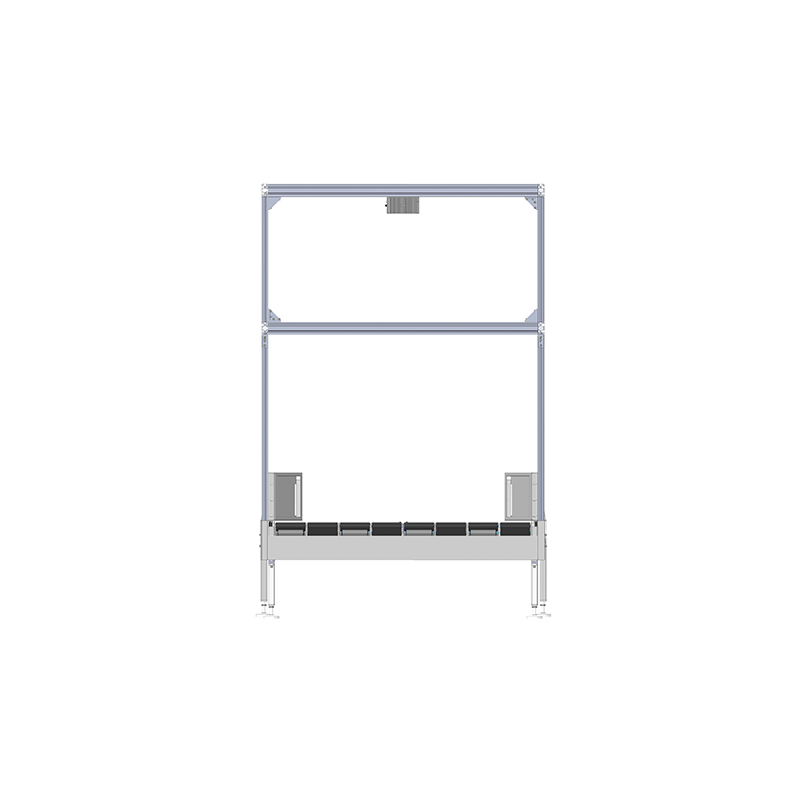

Driven by the explosive growth of the e-commerce industry, logistics and warehousing systems are facing unprecedented challenges in efficiency and accuracy. With tens or even hundreds of thousands of parcels arriving daily, the key to the success of the entire sorting chain lies in how to quickly, stably, and without damage transform these mixed and stacked batches of parcels into a "single-item flow." The 2D bulk flow singulator was developed to address this challenge. As a highly efficient separation device specifically designed for logistics and warehousing, it solves problems such as parcel congestion, overlap, and tipping at the source through its unique mechanical structure and intelligent control logic, significantly optimizing the overall processing flow of e-commerce warehousing.

Achieving Efficient Transformation from "Batch to Single Item"

Parcels received by e-commerce warehouses often come from multiple channels and vary in form—a mix of cardboard boxes, express bags, and foam boxes, ranging in size from the size of a palm to half a meter square, and often enter the sorting line in a stacked and compressed state. Traditional belt conveyors struggle to handle such disordered input, easily leading to multiple packages running in parallel, jamming, or tumbling, resulting in subsequent scanning failures or sorting misalignments. The 2D bulk flow singulator, however, uses a dual-axis cooperative motion system to "spatially decouple" dense package flows. When a package enters the equipment inlet, the lateral mechanism gently moves at a preset rhythm, coordinating with the speed gradient changes of the longitudinal belt to create temporal and spatial separation gaps between adjacent packages. This process, like "combing through tangled hair," transforms a chaotic batch into a uniformly spaced, stably positioned sequence of individual packages within 3-5 seconds, providing ideal input conditions for downstream equipment.

Improving the success rate of identification and sorting in subsequent automated processes

Modern e-commerce sorting heavily relies on automatic identification technologies, such as high-speed barcode scanning, volume measurement, and AI visual classification. These systems have stringent requirements for the individuality, stability, and consistent spacing of packages. If two packages pass close together through the scanning area, the system may misclassify them as one, leading to information loss or routing errors; if a package tumbles, the barcode cannot be effectively read. The "standard single-item flow" output by the 2D bulk flow singulator ensures that each package passes through the detection point independently, face up, and at a uniform speed, increasing the scanning success rate from below 85% to over 99.5%. This not only significantly reduces manual verification costs but also avoids misdeliveries and omissions caused by information errors, directly improving customer satisfaction.

Adapting to diverse package formats, ensuring processing flexibility

Addressing the characteristics of e-commerce packages—"small batches, multiple categories, and non-standardization"—a high-quality 2D bulk flow singulator possesses adaptive adjustment capabilities. Its lever spacing, operating frequency, and belt speed can be remotely set via the HMI interface or central control system, quickly switching modes to handle mixed scenarios of large home appliances during promotional seasons and small everyday clothing items. Some high-end models also integrate photoelectric sensors and AI edge computing modules, enabling real-time perception of package density and size distribution, dynamically optimizing separation parameters, and achieving "intelligent flow management." This flexible processing capability allows the equipment to cope with business fluctuations without downtime, greatly improving the responsiveness and resource utilization of the warehousing system.

Reduce Damage Rates and Maintenance Costs

Traditional separation methods relying on baffles, air blowing, or manual intervention are prone to package collisions, drops, or deformation due to compression, especially for high-value or sensitive goods such as electronics and fresh produce in cold chain logistics. The 2D bulk flow singulator employs a low-impact, gradual separation strategy, with all movements being gentle and controllable, almost entirely without hard contact, significantly reducing damage rates. Simultaneously, its simple structure, long lifespan of core components, and fewer maintenance points, combined with a predictive maintenance system, enable over 95% continuous operating time, minimizing production line downtime losses.

Integrate into the Smart Warehousing Ecosystem, Driving a Leap in Overall Efficiency

As a crucial component of the smart logistics system, the 2D bulk flow singulator is not isolated. It seamlessly integrates with upstream automated package feeders, cross-belt sorters, AGV scheduling systems, and WMS warehouse management platforms, forming a data loop. For example, when the WMS anticipates a batch containing a large number of irregularly shaped items, it can issue a "high-intensity sorting" command to the single-flow unit in advance; sorting results can also feed back into the algorithm to optimize the feeding rhythm of subsequent batches. This deep collaboration transforms the entire warehousing process from "passive response" to "proactive control," improving processing efficiency per unit area by over 30%.

In today's e-commerce landscape, where competition increasingly focuses on "fulfillment experience," every second of delay or misclassification in package processing can translate into customer churn. The 2D bulk flow singulator, with its precise, flexible, and highly reliable single-item flow generation capabilities, has become an indispensable "order maker" in modern smart warehousing. It not only optimizes the physical processes but also reshapes the logic of efficiency through data linkage—replacing chaos with order and making speed a result of precision.

Achieving Efficient Transformation from "Batch to Single Item"

Parcels received by e-commerce warehouses often come from multiple channels and vary in form—a mix of cardboard boxes, express bags, and foam boxes, ranging in size from the size of a palm to half a meter square, and often enter the sorting line in a stacked and compressed state. Traditional belt conveyors struggle to handle such disordered input, easily leading to multiple packages running in parallel, jamming, or tumbling, resulting in subsequent scanning failures or sorting misalignments. The 2D bulk flow singulator, however, uses a dual-axis cooperative motion system to "spatially decouple" dense package flows. When a package enters the equipment inlet, the lateral mechanism gently moves at a preset rhythm, coordinating with the speed gradient changes of the longitudinal belt to create temporal and spatial separation gaps between adjacent packages. This process, like "combing through tangled hair," transforms a chaotic batch into a uniformly spaced, stably positioned sequence of individual packages within 3-5 seconds, providing ideal input conditions for downstream equipment.

Improving the success rate of identification and sorting in subsequent automated processes

Modern e-commerce sorting heavily relies on automatic identification technologies, such as high-speed barcode scanning, volume measurement, and AI visual classification. These systems have stringent requirements for the individuality, stability, and consistent spacing of packages. If two packages pass close together through the scanning area, the system may misclassify them as one, leading to information loss or routing errors; if a package tumbles, the barcode cannot be effectively read. The "standard single-item flow" output by the 2D bulk flow singulator ensures that each package passes through the detection point independently, face up, and at a uniform speed, increasing the scanning success rate from below 85% to over 99.5%. This not only significantly reduces manual verification costs but also avoids misdeliveries and omissions caused by information errors, directly improving customer satisfaction.

Adapting to diverse package formats, ensuring processing flexibility

Addressing the characteristics of e-commerce packages—"small batches, multiple categories, and non-standardization"—a high-quality 2D bulk flow singulator possesses adaptive adjustment capabilities. Its lever spacing, operating frequency, and belt speed can be remotely set via the HMI interface or central control system, quickly switching modes to handle mixed scenarios of large home appliances during promotional seasons and small everyday clothing items. Some high-end models also integrate photoelectric sensors and AI edge computing modules, enabling real-time perception of package density and size distribution, dynamically optimizing separation parameters, and achieving "intelligent flow management." This flexible processing capability allows the equipment to cope with business fluctuations without downtime, greatly improving the responsiveness and resource utilization of the warehousing system.

Reduce Damage Rates and Maintenance Costs

Traditional separation methods relying on baffles, air blowing, or manual intervention are prone to package collisions, drops, or deformation due to compression, especially for high-value or sensitive goods such as electronics and fresh produce in cold chain logistics. The 2D bulk flow singulator employs a low-impact, gradual separation strategy, with all movements being gentle and controllable, almost entirely without hard contact, significantly reducing damage rates. Simultaneously, its simple structure, long lifespan of core components, and fewer maintenance points, combined with a predictive maintenance system, enable over 95% continuous operating time, minimizing production line downtime losses.

Integrate into the Smart Warehousing Ecosystem, Driving a Leap in Overall Efficiency

As a crucial component of the smart logistics system, the 2D bulk flow singulator is not isolated. It seamlessly integrates with upstream automated package feeders, cross-belt sorters, AGV scheduling systems, and WMS warehouse management platforms, forming a data loop. For example, when the WMS anticipates a batch containing a large number of irregularly shaped items, it can issue a "high-intensity sorting" command to the single-flow unit in advance; sorting results can also feed back into the algorithm to optimize the feeding rhythm of subsequent batches. This deep collaboration transforms the entire warehousing process from "passive response" to "proactive control," improving processing efficiency per unit area by over 30%.

In today's e-commerce landscape, where competition increasingly focuses on "fulfillment experience," every second of delay or misclassification in package processing can translate into customer churn. The 2D bulk flow singulator, with its precise, flexible, and highly reliable single-item flow generation capabilities, has become an indispensable "order maker" in modern smart warehousing. It not only optimizes the physical processes but also reshapes the logic of efficiency through data linkage—replacing chaos with order and making speed a result of precision.